Asset Integrity and Inspection

Ensure the ongoing integrity, performance and safety of your assets

- Continued safety and efficiency

- Fully integrated capabilities

- Prompt remedial services

- Reduce unplanned downtime

Ensuring asset integrity is vital for the safety of your staff and the reliability of your operations.

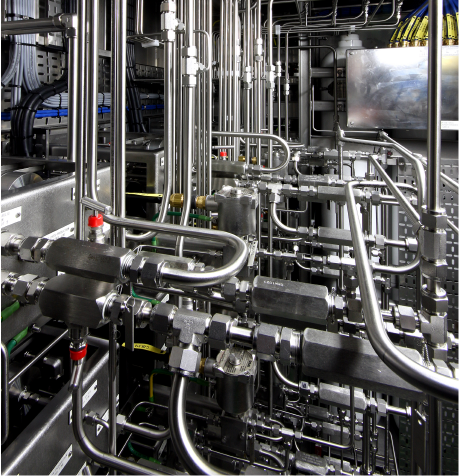

This is especially true for safety critical systems such as hydraulic and electrical controls, and high-pressure components including hoses and small bore tubing.

Our most popular inspection services include:

- ATEX/IECEx

- Instrument and Small Bore Tubing

- Hose Management

- Hydraulic Systems and Fluid Cleanliness

- Obsolescence Surveys and Reports

- Hazardous Area Inspection

- Electrical and Instrumentation

- Metering and Produced Water Treatment

Effective inspection is essential to:

- Ensure system safety and asset integrity

- Reduce environmental impact

- Enhance operational performance

- Prevent shut-downs

- Reduce costs

- Adhere to statutory regulations and prove compliance

Powered by Inspection Manager™

Through the inspection of your assets – regardless of original equipment supplier – SMS deliver all the benefits of a well executed inspection. But, we go one step further. We utilise the next generation in inspection software:

Inspection Manager is a fully digital and intuitive solution to support the effective completion of inspection checks on equipment.

Powered by Inspection Manager, our inspection team will fully assess your hydraulic and electrical systems whilst providing instant and actionable insights to support any remedial actions – all of which can be completed by the SMS Aftermarket Services team for a prompt resolution.

Inspection Manager can also be used to simultaneously collate punch points for any faults identified. Utilising the sync function, this provides:

- Real-time reporting of faults

- Usable insight to inform remedial actions

- Prompt action and feedback upon completion to reduce downtime

Watch the video to find out more:

Recent Projects

Small Bore Tubing Inspections

Development of a risk-based inspection strategy for SBT assemblies to prevent or mitigate HSE consequences that may result from a process safety or environmental release of hydrocarbon or high-pressure medium.

Meaning that SBT assemblies could be consistently assessed, tagged and categorised to advise of their current status, as well as inform future inspection and management planning.

The solution allowed our client to:

- “Register” individual assemblies to record their makeup and location

- “Manage” their assemblies through inspection and tagging

- “Report” on the status of their assemblies in a prompt and consistent manner

Ensure the ongoing performance and compliance of your operations

Speak to your local SMS team